How its done

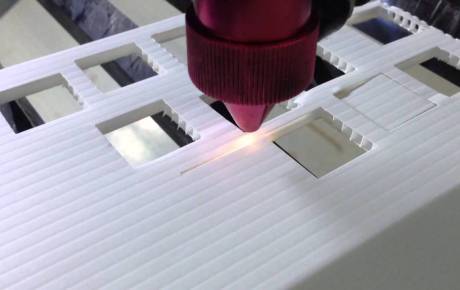

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics.

The laser optics and CNC are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material.

The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Some advantages of laser cutting

Like automated routers, laser cutters are guided by a CNC system. The essential difference, however, is that lasers cut not with friction but with heat.

A high-energy light beam burns through plastic rather than carving it away. While lasers aren’t right for every application, there are multiple advantages to this approach.

Precision Cuts

Whereas cutting with a router is akin to drawing with a magic marker, cutting with a laser is like drawing with a fine-tipped pen. As was mentioned, the width of a cut is limited by the width of the cutting tool. While the smallest router bits have a radius of just under 1 mm, the radius of a laser beam can be set to as small as 0.1 mm. Extremely detailed cuts can be made with dazzling precision.