Lined bending operation

Plastics such as acrylic can be formed (shaped) in different ways. One of the most popular methods of shaping plastic materials like acrylic is to fold (bend) it on a ‘strip heater’, at different angles.

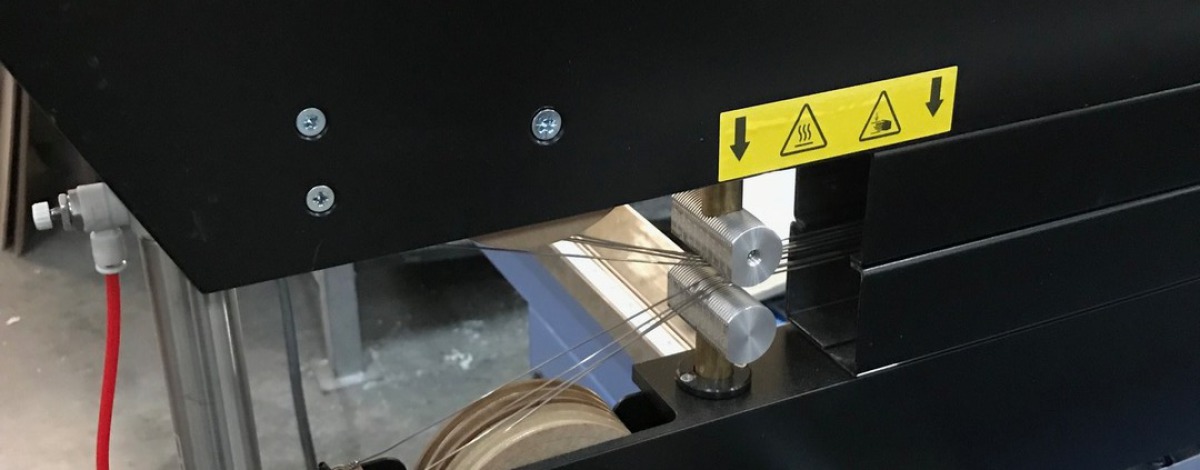

A heating element extends along the length of the strip heater and gives off intense heat when it is turned on.

The plastic to be formed is placed along the length of the heating wires positioned were the bend is to be formed. When the plastic is sufficiently heated through it is removed from the strip heater and placed in a bending jig were it is manipulated into the desired angle.

Products

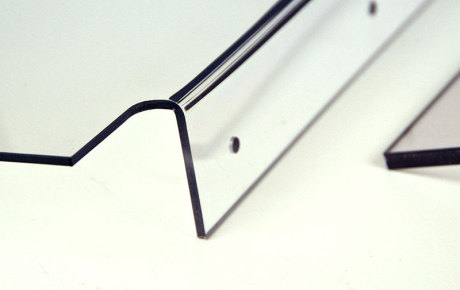

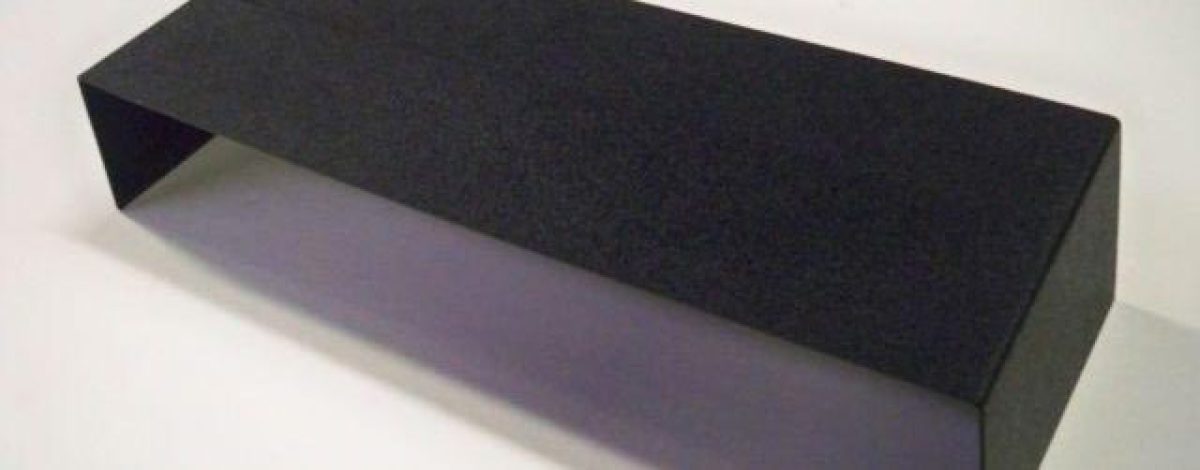

Bending plastic sheets give a seamless bend which unlike welding gives an aesethitic finish to the product.

This is especially beneficial when producing items that are in contact with food or liquids as there are no crevices wereby materials could become lodged.

Machine guards, point of display, covers and other items are comonly manufactured usuing these techniques.

Equipment

Our machines provide close tolerance plastic bending without any pretreatments, tight radius edges for crisp bends while having the capabilities to work with all thermoplastics like Polycarbonate PC, plexiglass, acrylic, PMMA, PVC, and PETG

Adjustable heating wires mean we can produce two close bends or large radius single bends.

The main features of our machine are;

- Bed length 2450mm

- Max material thickness 25mm

- Double sided heater beam

- Fully configurable heater to ensure correct set up for each job