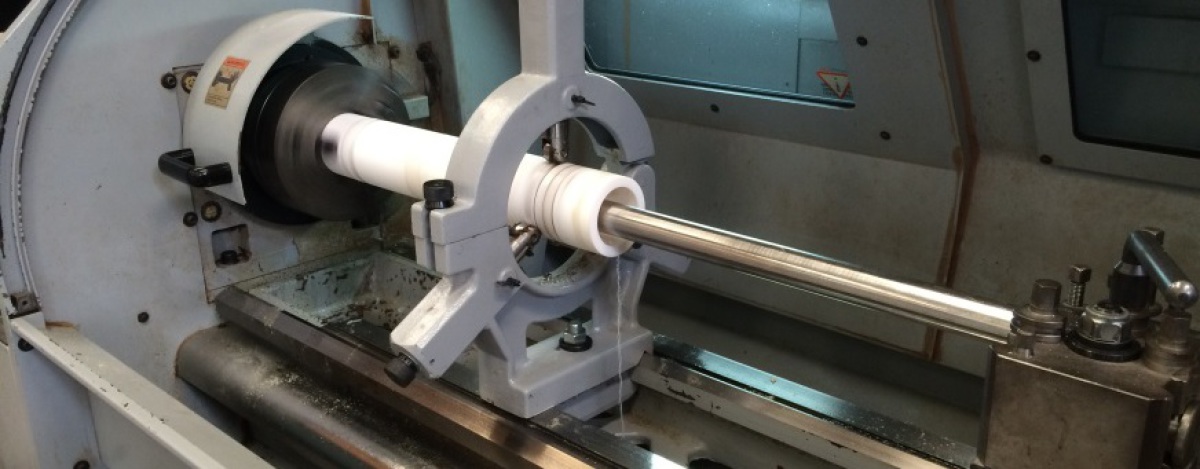

CNC Turning

Our CNC turning centres are capable of machining complex components to high tolerances with accurate repeatability.

We have developed methods of production that allows us to machine highly unstable materials to tight tolerances. We can program at the machine or remotely in our production office, from customer paper and CAD drawings.

We carry tooling for complex threads, single and multi-start threads.

We do machine Ceramics as well as laminates using specialist tooling and high extraction.

Materials and parts suitable for CNC Turning

Common materials that are often used to turn parts include; Nylon 6/66, Nylatron MoS2, Glass Filled Nylon, Peek, Acetal, HDPE, PE1000, PE500, PTFE, PVDF, PP, uPVC and many others.

Examples of parts that can be manufactured include Flanges, Nipples, Bushes, Bearings, Seals, Sleeves, Fastenings, Chevron Packs

Equipment

The latest addition to our fleet of CNC Lathes incorporates the following specifications:

- Swing over bed 560mm

- Spindle bore 104mm

- Distance between centres 1000mm

- Max 1800 RPM

- 900mm maximum swing

We are able to run one of prototypes through to high quantity production levels cost effectively and to the highest quality.