The 3d printing process

3D printing is any of various processes in which material is joined or solidified under computer control to create a three-dimensional object, with material being added together (such as liquid molecules or powder grains being fused together), typically layer by layer.

In the 1990s, 3D printing techniques were considered suitable only for the production of functional or aesthetical prototypes and a more appropriate term was rapid prototyping. Today, the precision, repeatability and material range have increased to the point that 3D printing is considered as an industrial production technology, with the name of additive manufacturing.

3D printed objects can have a very complex shape or geometry and are always produced starting from a digital 3D model or a CAD file.

Benefits of 3D printing

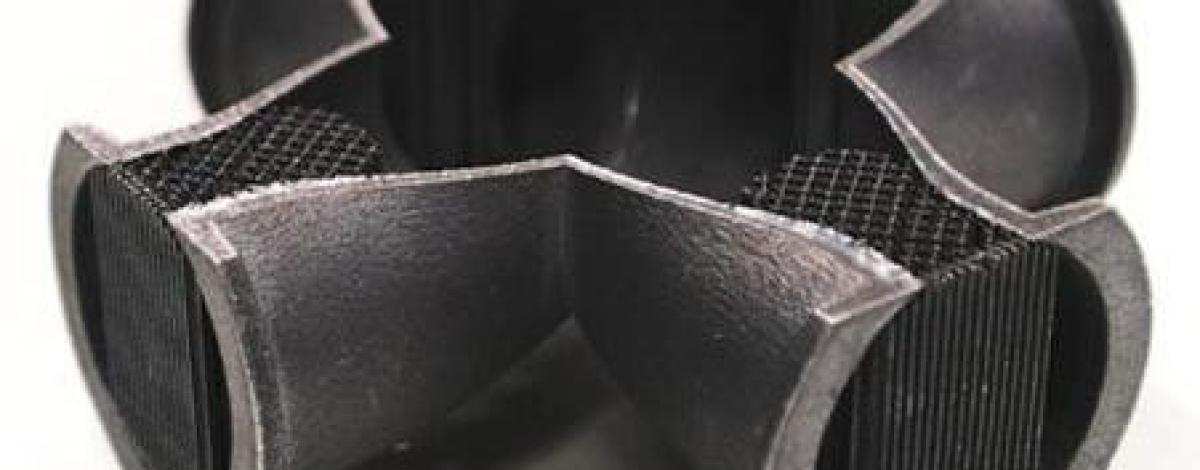

3D printing allows us to produce highly complex and intricate components that would be physically impossible to produce using traditional CNC operated machinery.

Additionally 3D printing does not necesitate the expense of having a mold or tool produced which mean start up costs are extremely low, in exxesence the cost is simply the material used and the time on the printer. Therefore,one off's or low volume becomes highly cost effective.

3D printing allows for easy customization. As start up costs are negiliable simply adjuctin g the digital 3D model allows for unlimited component customisation without costly mold and tool manufacture each time a change is required.

Most commonly plastics are used in the 3D printing process. However, as material technology advances it is now possible to print components that have inherant high strength or stiffness and high heat resistance. Composites are now com mon in 3D printing. Materials filled with Metals, Ceramics, Wood, Carbon, Glass, Fibres and other materials results in components that can be manufactured with unique properties for specific applications.

3D Printing compared with traditional manufacturing methods.

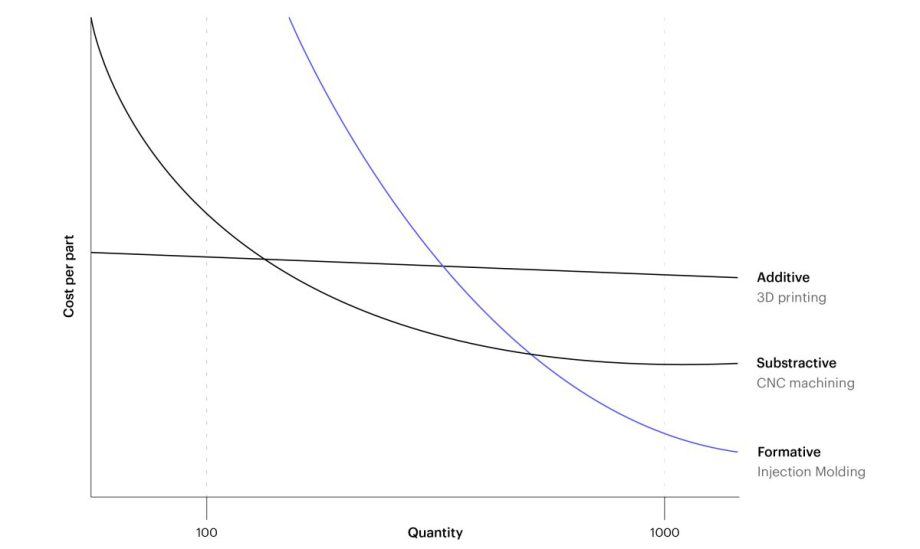

When choosing between an additive (3D printing), subtractive (CNC machining) or formative (Injection Molding) manufacturing technology, then there are a few simple guidelines that can gudie your decision.

Generally speaking we can say that:

"3D printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a low-cost or when the part geometry cannot be produced with any other manufacturing technology."

Choosing a subtractive technology (CNC machining) makes more sense in the following scenarios:

- Medium volumes: When producing parts in the 100's, then CNC machining is typically more economical. This is because the economies of scale start to kick in.

- Relatively simple geometries: Especially for metal parts, when the design can be manufactured easily through a subtractive process then CNC machining is the best option.

- High material requirements: When excellent material properties are essential, then CNC machining is a better option, as 3D printed parts typically have a lower strength.

- High dimensional accuracy: For functional parts with tight tolerances, CNC machining is the best option. For complex geometries, a hybrid approach (print first, CNC machine afterwards) is also be a viable option.

For larger production (> 1000 parts), formative technologies (like Injection molding) are more cost effective and usually make the most financial sense.

For a quick reference in the unit cost, use the graph below. In this simplification, it was assumed that all technologies can produce the part geometry. When this is not the case, 3D printing is generally the preferred manufacturing solution.

Therefore we can simplify the benefits of 3D printing as follows:

"3D printing offers great geometric flexibility and can produce custom parts and prototypes quickly and at a low-cost, but when large volumes, tight tolerances or demanding material properties are required traditional manufacturing technologies are often a better option."